The jewellery trade can be a complicated and gruelling industry, dominated by long hours at the bench, difficult orders to fill and hard-to-please customers.

With that said, more and more jewellers are choosing to ‘sail in smoother waters’ by embracing emerging technologies.

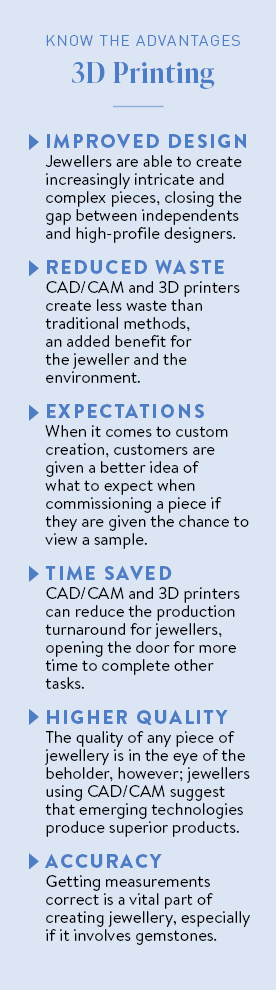

Advances in science and technology reshaped a number of retail industries over the past 10 years and few practices have had as much of an impact as Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM).

As many retailers told Jeweller, CAD/CAM offers virtually unlimited design potential and opens the door to previously unimaginable possibilities.

By utilising these tools, jewellers are able to design and manufacture pieces of the highest fashion and quality for an increasingly affordable price to the customer.

In other words, high fashion and ‘big ticket’ jewellery is no longer the exclusive province of the major brands and elite designers.

An experienced operator can break down a design into separate pieces to ensure manufacturing and finishing to a high standard is easier.

These jewellers no longer have to feel daunted by intricate designs that would once take many agonising days or even weeks to make by hand.

In one sense the ultimate beneficiary is the customer, who receives the jewellery of their dreams at a price that doesn’t ‘break the bank’.

With that said, these forward-thinking jewellers also enjoy the benefits of not only another happy customer, but also as an improved reputation in their respective market.

For others, great importance is placed on the satisfaction of a job well done. One such jeweller who fits the description of an ‘experienced operator’ is Carlo Romeo, of Carlo Romeo Jewellers in Kewdale, WA.

Romeo has worked with jewellery since the 1980s, and today uses 3D imaging to provide customers with the chance to review pieces before they’re manufactured.

When customers are satisfied with the design his staff then creates the piece using gemstones and precious metals.

“The most important benefit of working with these technologies is the increased speed and reduction in time spent completing a project from start until finish,” he explains.

“We can show our customers a life-like render as well as photos before the final product is made. This increases the chances that they’ll be happy when all is said and done.”

He adds: “We can also print a resin sample and physically showcase the piece to the customer.”

Nearly 4,000 kilometres away in Sydney, jewellery designer, and gemmologist Maria Kostina applies her craft at the business she founded in 2021 – Maria K Jewellery.

She agrees that the ability to work closely with customers during the design process is the most vital benefit of CAD/CAM manufacturing.

“Nothing beats showing your customer the piece during jewellery design - 2D drawings are great of course, however; sometimes they can be misleading,” she tells Jeweller.

“With CAD you could show the design through realistic renders and also 3D print the model for the customers to try on.”

“This way the customer knows what to expect and even those particularly fussy customers can be satisfied.”

|

SRINKIA (GUINNESS RECORD 2022)

Renani Jewels created this watch with

17,512 certified diamonds totalling 53.98-carats. | Marigold (GUINNESS RECORD - 2020)

Renani Jewels set this intricate ring with

12,638 certified diamonds totalling 47.70-carats. | AMI 'Immortality' (GUINNESS RECORD 2022)

The ring is set with 47.70-carats of IGI certified diamonds |

|

Power of precision

With more than 40 years of experience, Romeo has witnessed tremendous shifts in the trade as technology has slowly but surely taken over many responsibilities once managed by hand.

In Victoria, it’s a matter of the same principles with slightly different messaging at another technology-driven jewellery store.

Based in Roweville, the staff at Vahe Jewellery are taking a unique approach to retail – the store is alive with the sights and sounds of a bustling workshop as bench jewellers remain hard at work.

It’s a sharp contrast to the typical quiet elegance of a jewellery store, where director Eric Kojadelian was introduced to the trade by his father.

Kojadelian says the importance of technology in manufacturing is all he’s ever known as something of a ‘new generation’ jeweller.

“I’m a firm believer in the importance of CAD/CAM and 3D printing in our trade. It really is the way to go, at the end of the day you can accomplish so much which you can’t do by hand,” he tells Jeweller.

“When my father introduced me to the business he told me on day one that the days of doing things by hand are over.”

He says that it’s never a matter of simply printing and casting a ring in one piece and ‘rushing’ through the job,

as the end result with that attitude is typically a poor finish.

He offers a comparison to imported mass-produced jewellery and says that Australian customers expect and deserve better.

“I model my pieces in multiple parts, before cleaning and polishing each individual piece before assembly. This gives me a finish that is as good as something that’s handmade,” he says.

“It would be wrong for me to say these tools made my job easier because it’s all I've ever known. We made a major switch to resin printing a few years back.”

“We are able to produce smoother surfaces and better wire work. With wax printing, the surfaces were rough and required so much cleaning that it would change the dimensions of the model.”

Romeo agrees with Kojadelian and says that it’s not unreasonable to suggest that the end result is of a ‘higher quality’ compared with traditional methods.

“CAD/CAM and 3D printed jewellery are definitely higher quality and importantly when it comes to the gemstones, you get the added benefit of accurate measurements,” he says.

“The other major benefit worth remembering is the reduction in waste that we find with manufacturing with 3D printing compared with hand-made work.”

“I think that’s something everyone agrees is a positive.”

Kostina says that the importance of specific and accurate measurements cannot be understated.

“One of the key benefits of CAD/CAM technology is precision, calculating costs and having a good quote for the customer,” she explains.

“Then there’s knowing how many stones will be applied in the process and how many grams of metal will be used towards the design.”

“A business can save time when creating complex designs as everything is printed and cast. There’s cleaning and assembly left to do; however, all the important calculations have been made.”

|

SEA URCHIN ON THE ROCKPOOLS RING (JAA PEOPLE'S CHOICE WINNER 2022)

Maria Kostina was Inspired by Sydney's northern Collaroy rockpools for this intricate piece crafted in 18-carat white gold and set with over 200 white diamonds totalling 2.75-carats, 1.20-carats of sapphires and Akoya pearls. | | EUTIERRIA RING (GUINNESS RECORD 2023)

In 2023, HK Designs and Hari Krishha Exports broke the Guinness World Record for the most diamonds set in one ring with a design that symbolises becoming one with nature. It is set with 50,907 diamonds. |

|

Increasing demand

Due to early success with CAD/CAM, some businesses elect to overhaul methods of manufacturing and purchase new casting and finishing machines.

A jeweller can develop their own alloys and procedures and as a result, become an ‘in demand’ creator of unique designs as every piece is a one-off.

One retailer told Jeweller that it would be impossible to maintain the current volume of work without CAD/CAM and that they feel they are ‘better jewellers’ as a result.

This business now works with other Australian manufacturers in order to meet their demand by supplying them with CAD files before each piece is hand-finished in their workshop.

Back in Sydney and Kostina says that it’s not uncommon to hear tales of retailers enjoying a strengthened reputation among customers after embracing CAD/CAM.

“Quotes are definitely easy to do as CAD is so precise and there are no surprises for the jeweller or the customer,” she says.

“Through CAD and 3D printing, customers can try on the pieces and see if there are any minor alterations that need to be applied to perfect the design prior to making the real piece.”

“This saves time overall and realises their expectations.”

She adds that the sense of personal satisfaction and the joy of a ‘job well done’ makes work all the more rewarding.

“As a designer myself I feel so much empowerment when designing in CAD because I feel in charge of the design,” she says.

“I didn’t need to pass on any information to another designer on what I’m expecting.”

“I can play around with the piece in 3D and understand the various options if we need an alternative. It’s a very rewarding process.”

Success in business can be measured in many different ways. Some look at the ‘bottom line’ and profit, while others such as Kostina value a sense of happiness generated by their work.

More often than not it’s a combination of multiple factors. Jewellers have many reasons to strive for success, such as providing a comfortable lifestyle for themselves and their families.

Kojadelian says that at the end of the day, it’s about putting food on the table – a task that’s easier accomplished by harnessing the power of technology.

“I would say the most significant benefit of working with CAD/CAM and 3D printing technology is having the ability to produce things I simply wouldn’t be able to by hand,” he says.

“However at the end of the day, I just don’t think you can turn a profit by spending more than 40 hours each week hand-crafting a complex ring.

“As my father told me, those days have come and gone.”

Of course, these are not the experiences of every jeweller and indeed, many customers still value the ‘authentic’ appeal of a hand-crafted original piece.

That demand will still need to be met by some; however, for so many other jewellers change is in the air.

From sketches and handmade models to 3D imaging and creation, the industry has changed significantly in recent years and due to the many advantages these advancements present jewellers, it would appear that they are here to stay.

Read eMag