When consumers consider the origins of jewellery, whether it be shiny precious metals or dazzling diamonds and gemstones, it can be difficult to sell a story of environmentalism.

Mining conjures thoughts of crude machinery digging deep beneath the Earth’s surface, extracting raw materials and leaving behind giant craters and mountains of dirt.

One way or another, these perceptions need to be challenged when securing the jewellery industry's future.

Indeed, forging a relationship with the next generation of jewellery consumers is crucial to the future success of your business. So, what is the consumer of tomorrow looking for in a business?

The answer is increasingly ‘purpose’. Consumers desire long-term partnerships with businesses and brands they perceive as invested in the world outside the four walls of their store.

According to an intriguing report by US-based marketing consultancy firm Edelman, two-thirds (64 per cent) of consumers said they would purchase or boycott products from a company based on a social or political issue.

An increase in ‘belief-driven buyers’ was identified in markets worldwide, and it wasn’t a trend restricted to any specific income bracket.

Of the 8,000 people surveyed, more than half (53 per cent) said they believe that brands and businesses can do more to resolve social issues than governments.

A similar number (54 per cent) said they believe it is easier for brands and businesses to address social issues than governments.

“Brands are now being pushed to go beyond their classic business interests to become advocates,” CEO Richard Edelman says.

“It is a new relationship between company and consumer, where a purchase is premised on the brand’s willingness to live its values, act with purpose, and if necessary, make the leap into activism.”

Business consultants Retail Doctor Group have suggested that the desire for businesses to focus on sustainable practices increased during the pandemic.

Head of insights Anastasia Lloyd-Wallis says priorities changed as consumers had time to reflect on the global supply chain's environmental impact.

According to one study, 46 per cent of Australians reported that their values and ‘how they look at life’ have changed significantly since the pandemic.

“Sustainability – and sustainable practices – have long been on people’s minds, so this trend is really no surprise,” she says.

“Increasingly concerned about the amount of packaging used, its impact on the environment, and how we can reuse or recycle products, shoppers are looking to change their planet-saving behaviours, patterns, and habits.”

This approach to consumer demands is not without fault. The Harvard Business Review published a report in 2019 that identified what’s known as an ‘intention-act gap’ in purchasing patterns.

More than two-thirds (65 per cent) of respondents to one survey said they want to purchase products from ‘purpose-driven’ brands; however, just 26 per cent confirmed they actually make these purchases.

With that said, what if this figure improves in the future and more consumers follow through on these supposed demands?

Where will your business be positioned if the day ever comes that consumers ‘vote with their wallets’ in favour of jewellery stores that have taken a clear position on the importance of environmentalism?

|

|  |

| Furnaces are used to melt precious metals at Morris and Watson. | Wax injection during the casting process at Morris and Watson. |

|

One step at a time

Improved access to 3D printing services has significantly reshaped the jewellery industry in recent years.

As an increasingly cost-friendly practice, many hoped that 3D printing would herald a new age of environmentalism in mass production.

The dream was that traditional mass manufacturing methods would evolve with the use of CAD and 3D printing. As is often the case, it’s a more complicated story than that; indeed, there is no ‘silver bullet’ solution.

For example the use of CAD/CAM manufacturing has the potential to reduce and eliminate the need for mass manufacture in favour of producing one-off bespoke pieces in a cost-effective and efficient way.

However, manufacturing 3D printers and materials then creates a new industry of mass manufacture. This requires significant energy and resources, and as a new industry may have a large environmental impact as manufacturing processes haven’t been developed to their full potential.

At Rapid Casting in NSW, Ben Farago oversees Australia’s most extensive suite of 3D printers, offering services to jewellery businesses worldwide.

Farago offers a pragmatic perspective on sustainability and says the jewellery industry is moving in the right direction.

“We have to be realistic. Casting and refining is no different to any other industry – everyone tries their best to minimise the waste they produce and the energy they consume; however, at the end of the day, if you want to produce something, there will always be a by-product,” he tells Jeweller.

"It is also important to remember that the jewellery trade is built on the consumption of precious metals and gemstones. Yes, we have come a long way from gold and diamonds dug out of the ground by children in third-world countries, but whether we call it ethical and fair trade, there is no way to greenwash the environmental impact of mining."

He added: “It’s the same discussion we hear with electric cars. They might use less energy than a traditional vehicle, but what is the environmental cost to manufacture them?"

For retailers dealing with consumers concerned about the environmental impact of the trade, Farago highlighted an interesting point of consideration – the sentimental value of fine jewellery.

He said that many people purchasing fine jewellery – whether it’s gold, silver or platinum – hope the piece will remain within the family for many generations.

If a piece of jewellery passed down from generation to generation over many decades – with each owner adding new memories and emotional attachments to the piece – then perhaps it’s a worthy exchange.

“It might be fair to say that the jewellery trade is better positioned than other industries because of the sentimental value we add to an already physically valuable object," he explains.

“It’s hard to argue that fast fashion hasn’t slowly started to creep into the jewellery trade; however, with the introduction and development of CAD/CAM, one of the big changes we have seen is the opportunity for customers to create unique custom pieces at an affordable price.

"This means more everyday people can afford to have a generational piece of jewellery custom-made whereas 20 years ago it would have been unaffordable."

|

|  |

| A furnace is loaded during the casting process at Morris and Watson. | Gold bullion created by Chemgold. |

|

Changing public perception

The good news is that many Australian jewellery suppliers are proactively restructuring their practices to satisfy these consumer demands.

For example, consider BECKS, the South Australian supplier of precious metal products and services.

In recent years, the company has completed a review of its production facilities in search of more environmentally friendly options.

BECKS has adopted more energy-efficient lighting, installed timers on equipment to prevent excess power usage during out-of-hours operation, and began using hybrid corporate vehicles to reduce consumption and carbon footprint.

Perhaps most significant of all, the company is using electricity for all of its equipment to better use the state’s power network, fueled by 70 per cent renewable sources.

“We consider the impact of all aspects of our manufacturing and business operations on the environment and community and have initiated several changes in our business practices to reduce negative environmental impact,” managing director Greville Ingham told Jeweller.

“BECKS is committed to continuous learning and innovation. This is especially true in the area of sustainable manufacturing and business operations.

“We are looking at the environment our people work in where we are burning, polishing – activities that produce emissions. We test our air quality and ensure we are working in safe conditions.”

There’s also been a renewed focus on the social impact of the business, shaping policy based on three key pillars – ‘our people, our planet, and our product’.

Ingham says that BECKS hopes to change this public perception with its expanding range of initiatives.

“As a precious metals recycler, the heart of our business operates as a circular economy. We have extended this thinking beyond those core commodities with dedicated waste streams encompassing scrap metal, printer cartridges, liquid waste, batteries, fluorescent tubes, waste oils, paper, cardboard, and drink cans, to list just a few,” he explains.

“By carefully managing these waste streams within our operations, we have significantly decreased our environmental footprint and contribution to landfill while fostering responsible waste management within our teams.”

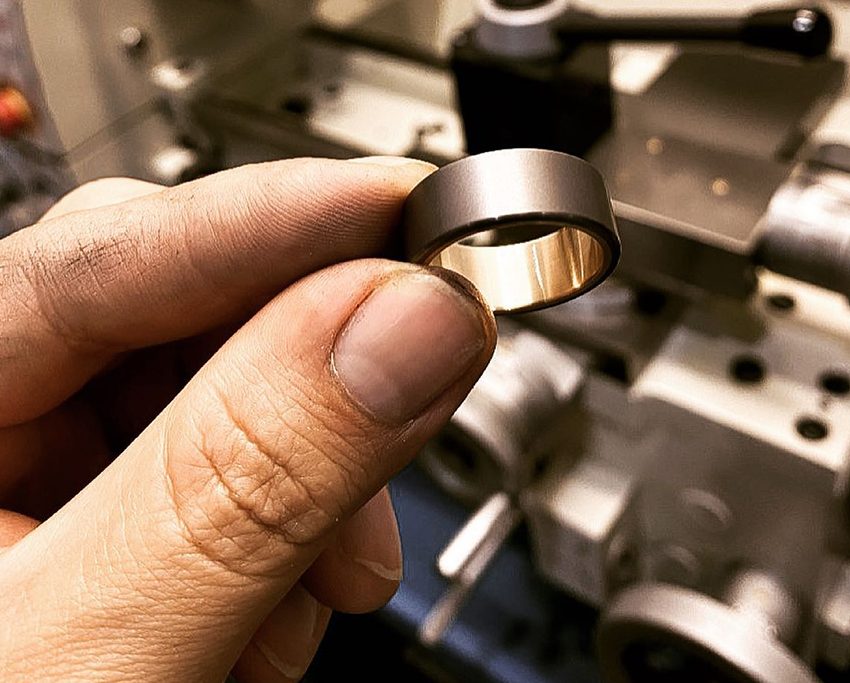

|

|  |

| Close inspection of a wedding bang at BECKS. | Palloys wax models created by Chemgold during the casting and refining process. |

|

Going above and beyond

The reputation of the precious metals industry is also important to the staff at Chemgold. This business has worked hand-in-hand with jewellery retailers for over 40 years.

Chemgold offers CAD/CAM, casting, refining and finishing services, and director Darren Sher says that environmentalism has been a priority for the company for many years.

“In recent years, Chemgold has proactively responded to the increasing demand for eco-friendly and responsible practices in the precious metals and fine jewellery industries,” he tells Jeweller.

“We recognise that the reputation of the precious metal industry is intricately linked to its impact on society and the environment. As a result, we have introduced state-of-the-art measures to minimise our environmental footprint.”

These measures include using advanced kilns imported from Japan and Germany, equipped with cutting-edge exhaust systems and afterburners. This equipment ensures that emissions are effectively eliminated and reduces pollution.

Chemgold has also adopted a steam dewaxing process, significantly reducing environmental impact during manufacturing.

The company has also taken a strategic approach to water management, effectively managing consumption and waste to mitigate environmental impact.

Sher says this commitment to sustainable operations is more than a mere reaction to industry trends.

“We acknowledge the profound impact of our industry on both the environment and society, compelling us to adopt a comprehensive approach to address these concerns,” he says.

“In our precious metal sourcing and casting procedures, we take immense pride in our conscientious practices. We provide an unequivocal guarantee that our precious metals are sourced from ethical, recycled, or responsible origins.

“In our casting process, we implement the latest recycling methods available in the market, underscoring our unwavering commitment to sustainability. We firmly oppose any activities that perpetuate conflict, violence, or human rights abuses.”

Partnerships with retailers

Other key players in casting and refining have forged partnerships with major retailers to showcase their commitment to environmentalism to consumers directly.

Earlier this year, Michael Hill International – with 275 stores in Australia, New Zealand, and Canada - launched a new gold recycling program.

The company is encouraging consumers to exchange broken, old, and no longer worn gold jewellery pieces in return for value on a Michael Hill gift card.

“We are fortunate to work with precious metals that never tarnish or decay, allowing us to provide an innovative service whilst building a more circular economy,” CEO Daniel Bracken explains.

“How we source and manufacture our products impacts our planet, and this program is our first major foray into jewellery circularity and evolving the jewellery industry towards a more sustainable and ethically responsible future.”

The program was launched in partnership with Morris and Watson, a family-owned precious metal refiner and casting house operating for nearly 100 years.

Head of sustainability, Kerrie Hockless, reported that the company recycled more than $200,000 of gold between April and July.

“We know through research that for every one gram of pure gold we can push back into recycling engineered products saves around three tonnes of mining ore and 16 kilos of carbon emissions,” she told Ragtrader.

Morris and Watson has previously described its precious metals recycling program as its ‘edge’ in the market, with fine-tuned refining designed with environmental impact in mind.

For example, melted and burnt exhaust is evacuated through afterburners and state-of-the-art smoke and particulate scrubbing systems. The refinery also uses a custom-designed air extraction system with an automatic pH dosing system monitored and recorded daily.

The company also has a comprehensive system of rainwater usage via roof catchment and tank storage used for melt machine cooling and recycling.

|

|  |

| Wedding band manufactured by Palloys. | Casting and refining requires extreme heat. |

|

Best is yet to come

Perhaps the most pleasing factor in this matter is that Australia’s casting and refining specialists acknowledge that while the progress has been positive, much work remains to be done.

Both Chemgold and Morris and Watson are members of the Responsible Jewellery Council, and Sher said that provided a valuable framework to structure these initiatives.

“Our membership is a testament to our unwavering commitment to upholding the highest standards of quality and ethical conduct. This membership ensures our strict adherence to the RJC's Code of Practices, encompassing business ethics, human rights, social impact, and environmental performance,” he explains.

“As a member of the RJC, we consistently uphold the highest standards in our industry. These initiatives are an integral component of our core values and set us apart as a responsible and sustainable leader in the precious metals and fine jewellery industry.”

At BECKS, Ingham says that his company has some significant plans concerning environmental strategy to work towards in the immediate future.

“We have begun an exciting journey to strategise our net zero pathway with our ultimate goal to become a carbon-neutral business before 2030,” he says.

“As part of this major initiative, we are not only addressing our carbon emission within our direct operations but also across our entire value chain. By addressing Scope 3 emissions, we aim to minimise the environmental impact of our business activities, further contributing to a cleaner, healthier planet.”

Casting and refining have a rich history, with historians suggesting that South American societies such as the Incas and Mayans used wax carving to create jewellery thousands of years ago.

Farago says this attachment to tradition has proven to be a double-edged sword regarding an increasing desire for ‘sustainable’ practices.

The desire to stick with ‘tried and tested’ methods discourage companies from exploring newly developed and more environmentally friendly techniques.

On the other hand, traditional methods tend to use less energy because they were designed when mass manufacturing was less advanced and energy-dependent.

“Jewellery is a very ‘old’ trade, and it can be difficult to find room for development,” he explains.

“Casting practices have changed over time, and 3D printing has been introduced, but we are using many of the same processes invented 50 to 100 years ago. We are also manufacturing the same products we always have, so we just have to do it better."

If the trend of ‘environmentally conscious’ consumers continue to increase, it’s important that your business can ease any concerns potential customers may have confidently.

Fortunately, many of Australia’s precious metals suppliers are moving in the same direction.

READ EMAG