The COVID-19 pandemic has disrupted countless industries, but consumer interest in jewellery has fared surprisingly well. Data from Retail Edge Consultants released late last year revealed November sales figures across the jewellery industry were as much as 20 per cent higher than what was seen during the same period in 2019.

The COVID-19 pandemic has disrupted countless industries, but consumer interest in jewellery has fared surprisingly well. Data from Retail Edge Consultants released late last year revealed November sales figures across the jewellery industry were as much as 20 per cent higher than what was seen during the same period in 2019.

Unable to travel, a significant portion of the public’s discretionary spending appears to have shifted towards luxury goods; and with Australia still months – if not a full year – away from fully resuming international travel, this increased interest in luxury purchases could be expected to continue for some time.

To fully capitalise on this, casters and refiners are developing new services and systems to be even more responsive to the needs of jewellers.

Chris Botha, operations manager at Palloys – part of the Pallion Group of companies – says, “Palloys has extensively increased its casting and refining capacity to handle the additional volume in the past year, and has also doubled its CAD and CAM printing capability to better manage the increased demand and casting capacity.”

Richard Hayes, CEO The Perth Mint – which refines the majority of the gold produced in Australia – has noted similar trends, “The vast bulk of Australian gold producers continue to entrust their refining needs to The Perth Mint.

“Additional refining and casting capacity has been commissioned over the last 12 months.”

With the increased demand from customers, combined with unpredictable metal prices, making use of every resource available will be crucial for making the most of current opportunities.

The gold standard

A sudden jump in the price of precious metals has made every piece of scrap, lemel, and sweep all the more valuable, highlighting the value of efficient casting and refining.

“The combination of precious metal prices and COVID- 19’s effects on business, particularly within the jewellery industry, has significantly increased the demand for Palloys’ refining services,” Botha tells Jeweller.

“Palloys refining jobs and scrap metal buyback numbers have increased over the past six months. As a result, Palloys now offers very competitive pricing and faster turnarounds.”

He adds, “Our sister company, ABC Refinery, completes all Palloys metals and refining services. In this way, from our casting alloys to our fabricated metal supply Palloys is the only jewellery manufacturer that can trace its precious metals supply directly to its primary source.”

Thanks to commodities being viewed as a safe store of wealth during uncertain times, the price of gold skyrocketed in 2020. After a record-breaking peak of over $US2,000 per ounce in August, its price has since fallen by approximately 15 per cent.

Hayes explains, “Precious metals have risen in price over the last 18 months due to a range of global macro- economic factors and geopolitical issues.

“These include massive amounts of fiscal stimulus – especially by the US government – inverted and/or historically low bond yields and interest rates, Chinese territorial and economic expansionism, and COVID-19.”

He adds, “The world has become a less certain place and investors have sought to manage their risk and exposure to more traditional asset classes, by diverting investment flows into precious metals.

“The rises in precious metals prices over the last 18 months have sparked renewed interest in precious metals as a store of wealth and a vehicle for wealth management for investors large and small.”

While still well above pre-pandemic levels, the sudden changes in direction have had a substantial effect on gold’s availability, which will impact supply for the foreseeable future.

“Currently, we are experiencing gold, and other precious metals, showing extreme highs followed by price contractions within a relatively short period of time,” Peter Beck, director Peter W Beck – which includes a Precious Metal Services division – told Jeweller.

“As a result, refiners are feeling the expected impacts of the price of gold both rising and falling. This in turn is having an effect on the supply and demand of precious metals.”

Hayes observes, “The increase in the gold price has made marginal gold deposits viable, which has increased refining volumes globally.”

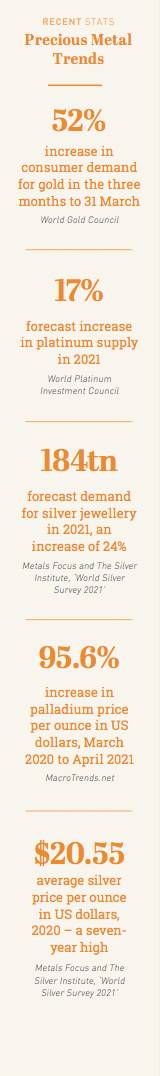

Likewise, silver has also recorded a remarkable surge; its price increased 137 per cent during 2020, compared with gold’s 38 per cent. According to international industry association The Silver Institute, the precious metal is expected to hit its highest level of demand in six years in 2021.

As restrictions on production – due to COVID-19 – are gradually removed, silver’s supply is also expected to increase, however growing demand from investors is expected to push its price higher.

Other precious metals are also being affected. According to Platinum Guild International, US platinum unit sales saw a 14 per cent increase in Q4 2020, compared with Q4 2019.

Likewise, China saw a 14 per cent increase of platinum jewellery fabrication over the previous year for the same period. A global oversupply of the metal, largely due to the decline of car manufacturing, has also kept its prices low.

Platinum’s higher margins – and the ability to drive incremental sales for jewellers – makes platinum products an effective value-add for many retailers.

Palladium, on the other hand, has skyrocketed in price, nearly doubling from its March 2020 low, owing to its application in reducing the carbon emissions of fossil fuel engines.

Post-COVID, as the market begins to become more predictable, some in the industry are beginning to see a return to normalcy.

According to Darren Sher, director Chemgold, demand for refining services is beginning to stabilise.

“Whilst there was a huge spike at the beginning of the pandemic and overall increased demand for majority of 2020, we have found that the demand has stabilised in the last three to six months,” Sher said.

“We have found an increasing amount of our clients are after their return as fabricated alloys or Chemgold- branded bullion.”

Additionally, this highly uncertain environment has shown the importance of recovering as much waste as possible. Adam Van Sambeek, treasury manager Morris & Watson, said this is critical even during the best of times.

“[Morris & Watson] not having a minimum refining quantity removes a barrier for the need for frequent turnover of precious waste. Customers tend to regularly recycle their lemel and waste back into cash or reusable semi-fabricated metal, partially offsetting metal cost in a rising market,” he explains.

At Pallion, Botha says, “ABC Refinery is Australia’s only independent London Bullion Market Association (LBMA), Shanghai Gold Exchange (SGE) and COMEX [part of the New York Commodity Exchange]-accredited refinery.

“Our ABC Refinery accreditations and reputation of a high-quality service has enabled us to increase our market share to 30 per cent of gold and 70 per cent for silver in the Australian market.

“We are now refining 100 tonnes of gold and more than 500 tonnes of silver per annum.”

As the major refiner for Australian mines, The Perth Mint is the only refinery to be fully accredited for both gold and silver with the LBMA, and is also accredited by SGE, COMEX, the Tokyo Commodity Exchange (TOCOM) and Dubai Multi Commodities Centre (DMCC).

|

| Left to Right: ABC Bullion; Peter W Beck |

Old science, new technology

Whatever new demands are placed on the industry, there are some factors that are simply impossible to change.

Says Hayes, “While a number of ‘new’ refining technologies marketed today show good promise, there still remain drawbacks.

“For example, one such process is unable to remove copper from ore, necessitating a secondary refining process, negating some environmental benefit claims. However, some of these technologies will undoubtedly evolve into sustainable future solutions.”

Beck explains, “Gold, silver, platinum and palladium refining, and the techniques used revolve around electrowinning and chemistry. Electrowinning and its behaviour are governed by the laws of physics, chemistry is likewise governed by the laws of chemistry.”

While electrowinning – the process of separating metals from impurities – may not have drastically changed from its discovery in the 1800s, there are new efficiencies to be had.

“Efficiencies can be gained by good material management and procedural management,” Beck adds. “The art of a refiner is to take the timeless principles of electrowinning and chemistry and by using the best equipment and practices, to make the process as efficient as possible.”

There are some exciting developments in this space. Van Sambeek said Morris & Watson has invested in more environmentally friendly processes in order to recover 80 per cent of the nitric acid from the fume stream before it reaches the chemical scrubbers.

“This dramatically reduces the workload on scrubbers, eliminating potential environmental contaminates and recovers acid that can now be recycled,” Van Sambeek said.

“We are expanding the use of this technology to recycle even more chemicals.

“We’ve also invested in a state-of-the-art furnace for burning sweeps. This world leading furnace technology results in a cleaner more efficient use of energy.”

Van Sambeek said these solutions are economically responsible – both financially prudent and better for the environment.

“Over the past two years we’ve been upgrading our refining facility with the latest European technology.

“There are improved processes, reducing handling of harmful chemicals and a much cleaner and efficient output. It’s safer for staff and the environment,” he said.

Meanwhile, Botha says, “ABC Refinery is the largest independent precious metals refining facility in Australasia. ABC Refinery is the benchmark in Australian eco-friendly refining.

“In 2021, it invested in an additional 175kg acidless separation (ALS) refining technology to service the value-added demand.”

He added, “ALS is the world’s most environmentally safe refining technology and produces no noxious residue. ABC Refinery is the only Australian refinery that employs this technology.”

In addition, ABC Refinery’s technology is – uniquely – accredited by the National Association of Testing Authorities, International Organization for Standardization, Commission E´lectrotechnique Internationale, Australian Standards and International Laboratory Accreditation Cooperation.

The Perth Mint has also made strides in its environmental policy, appointing a chief sustainability officer and “actively participating” in the West Australian government’s “carbon neutral future” strategy.

In addition, Hayes says, “Capital investment at the Mint’s refinery has amounted to $36 million over the past 10 years, with $17 million of this being invested over the last four years.

“Spend has been spread across new equipment, increased capacity and improved environmental management.”

He adds, “A new assay laboratory was commissioned a few years ago, equipped with the latest state of the art equipment and technology to ensure its assays and return of metal to customers is of the highest accuracy.

Additionally, “Automation is regularly adopted to ensure repetitive or potentially dangerous tasks are performed by machines, minimising or eliminating the risk of injury to employees.”

|

| Left to Right: ABC Bullion, Pallion |

Beyond the human hand

From the design side of jewellery production, technology breakthroughs in the field of casting are creating new opportunities for jewellers, including designs previously thought to be impossible.

This is being driven by improvements in 3D printing; a technology that has had a dramatic effect on the industry over the past 10 years. The fall in cost of the average 3D printer, alongside the increasing detail now possible in prints, is leading to significant achievements.

One example is the ‘arms race’ in breaking the world record for the most diamonds set in a ring. Hallmark Jewellers, based in Hyderabad, India, unveiled ‘The Divine’ in September last year, which features 7,801 set diamonds, arranged in a flower design.

However, they did not hold on to the record very long, with Renani Jewels, from Meerut, India, displaying ‘Marigold’ just a few months later, set with 12,638 diamonds – demolishing the previous record.

These feats have been possible largely thanks to advances in 3D printing. Imaginarium, an Indian 3D printing service, played a critical role in creating the mould from which ‘The Divine’ was cast.

The company is working to push the limits of what can be achieved in casting, and producing moulds that would be impossible to do by hand.

“The sheer amount of design freedom that 3D printing brings with it is incredible, so much that complexity of a design is no longer a factor in manufacturing,” Kamlesh Parekh, founder Imaginarium, recently wrote.

“Designers now have options to experiment with abstract patterns and shapes that make for visually striking pieces of jewellery.

“If a designer can produce it on a computer, the 3D printer will print it, no questions asked.”

Jewellers closer to home can take advantage of more practical and realistic benefits offered by 3D printing, with several casting houses offering the service.

In October last year Palloys, AGS, PJW, Regentco and A&E Metals – all part of the Pallion group of companies – launched a new all in one platform that allows jewellers to place customised 3D print orders.

The platform, which took two years to design and implement, allows jewellers to upload a CAD file and receive an instant quote for a finished piece, including everything from print to mould, casting and finishing.

“The instant quoting for CAD files, casting from their own mould library, fabricated metals and diamonds allows jewellers to enjoy accurate and instant quotes they can pass onto their customers, giving the jewellers an instant competitive advantage,” Alison Habbal, assistant operations manager – jewellery at Palloys told Jeweller at the time.

Botha adds, “Palloys.com is significantly outperforming the previous website and has already exceeded expectations within the business and industry.

“Palloys’ customers can now order a customised piece, including certified diamonds, online and receive them as a raw cast, semi-finished or fully finished.

“We also offer desprue and tumble options for castings which have been very popular since launching the website.

We have seen online orders for the jewellery division more than double in the new year as more people adopt the platform.”

Elsewhere, Botha notes that the Palloys research and development department has also been working on “direct metal printing for the bullion and jewellery sector, and adding subtractive prototyping back into our manufacturing processes.”

Unstable metal prices have emphasised the important of efficient and effective refining, and new technologies are allowing jewellers to customise pieces to a level that was previously impossible. Both of these developments will be important to meet the needs of customers in 2021 and beyond.

Read emag